Inspector Communication in the 21st Century

I have been inspecting long enough that I remember delivering paper reports to all my clients. Since that early start, I have adapted to the times by substantially modifying the report from the "Acceptable, Marginal, Defective" format so prevalent to a more granular report with eleven categories. I deliver the report electronically, from the house, using my phone as a hotspot.

Back then, we did everything by phone and I even had an 800 number for out of state clients. Technology kept marching, and I went right along with it, dropping the 800 number when everybody had cell phones. I don't own a fax machine anymore, either.

That march continues. Video conferencing used to involve massive amounts of equipment that only a large corporation could afford. Today we carry it in our pocket. For my out of state clients, I can contact them while at the inspection if I discover a major defect and we can talk about it right then and there. Not only that, but I can show them what I'm looking at with Skype, Google Hangouts, or Facetime.

The pace of change is thundering ahead. As an inspector, I can choose to keep up with it or turn into a dinosaur. (Seriously, there are still inspectors that don't take pictures!) My default position is that whatever I can do to improve the experience for my client while doing the most thorough inspection that I can is worth the effort to learn the new systems.

Those two items need to work in tandem. The best inspection in the world, poorly communicated, is worthless. Obviously, the reverse is true as well. The second biggest skill an inspector can bring to his job is the ability to talk to and educate the client. At every opportunity, we need to, as an industry, improve to meet our clients needs. They need to be able to talk to use. Video chats simply make that a much more personable conversation.

So, would you like to chat? And do you use any of these in your business?

Who swiped my square footage?

It's getting to the point where I much prefer doing a 1960's rambler over a new home. At least with them, I know what kind of problems to expect. Not so with new homes - and our builders are getting sloppy and the municipal building inspectors are missing defects, a lot of them.

Case is point, yesterday I did a new home, built last year and occupied in December. I followed my usual protocol of inspecting the exterior first, then roof, then interior spaces, starting at the finished basement.

I started at the store room at the back of the house, where the furnace was located. Lots of stuff in there in the rectangular room. That's when a warning bell went off. Made a "unh?" sound and ran up the stairs to fetch my laser measure.

Measured upstairs, from the sliding door to the far edge of the kitchen. 24'2". Add a six-inch wall. Measured the width of the laundry room. 11'1". Total, 35'9". Got it.

Ran back downstairs. Measured from one side of the store room to the other. 24'7".

Ran back upstairs, hurried past my clients. Got into the laundry room and stomped with my heel. Echo-y sound, so definitely not slab-on-grade. Basement or crawlspace. Checked the only closet. No access hatch. Stomp to make sure. Hatches bounce, making them sound slightly different that regular sub-floors. Nope.

Meanwhile, my clients are looking at me as though I am a touch daft. "What's under here?" I asked, pointing to the laundry room floor.

More looks questioning my sanity. Fortunately, I've worked with this couple before, so I get the benefit of the doubt.

I explain myself, that the dimensions don't match. Off we go, down the steps, 'round the corner, and we collectively stare at the store room wall. The husband asks if blueprints would help. "Absolutely!" They're friends with the sellers (it's a FSBO) so they text about plans and the crawlspace.

The reply comes back - they have no plans, nor is there a crawlspace.

Au contraire, I think, got to be something under there. It's not a slab, and it isn't a basement, so crawlspace is the default answer.

This, too, gets explained to the clients. They ask why I need to get in there, given it is a new home. I point out that I need to verify the insulation, vapor barrier, ventilation (I didn't see vents on the exterior wall, so it may not be vented, another code violation), and make sure it is dry. If it isn't dry, we have a potential mold and rot issue waiting for us.

Termites in Pullman are a very rare occurrence, fortunately, or I'd add them to my list of worries.

My clients are bright; they get it. They also don't panic as we analyze the best way to create access. The home is still under warranty, so the builder will be doing the work.

I felt pretty pleased. Like Sherlock in the story "Silver Blaze" with the dog that did not bark, I had done the harder part of inspecting. Any one can see what is there, but a really good inspector will recognize what isn't. It was a good catch.

Gregory (Scotland Yard detective): "Is there any other point to which you would wish to draw my attention?"

Holmes: "To the curious incident of the dog in the night-time."

Gregory: "The dog did nothing in the night-time."

Holmes: "That was the curious incident."

What the heck is CSST?

I get this question a lot, usually from someone angry that I said their CSST was not bonded properly. Electricians especially get annoyed with me, so let me take a bit of time and explain CSST and why it keeps popping up in (my) inspection reports.

Photo courtesy of SoCalGas.com

First, the acronym, CSST, stands for Corrugated Stainless Steel Tubing. This piping is used to transport gas within your home from point A to point B. Simple enough. The physical appearance is a flexible yellow hose-like gas line. The flexibility is one of the major benefits of the piping, eliminating the need to create seventeen turns in the line to get to a specific fixture such as the gas fireplace or stove. This reduction in installation expense compensates for the increased cost of the CSST. Black iron pipe is still cheaper; labor is still expensive, so CSST has earned a solid niche in the building industry. the reduction in fitted connections subject to gas leakage cemented the deal. Builders and code officials alike approved of Corrugated Stainless Steel Tubing.

However, since its introduction into the marketplace in 1990, we have learned a few things about CSST. The most important for me as an inspector is that CSST, while safe under almost all operating conditions, has one issue that necessitates special attention. That condition is an over-charge of electricity along the gas piping. Under those conditions, such as a close proximity lightning strike, the energy travels along the black iron and, when it reaches the CSST, can cause a failure in the flexible piping that creates a fire.

By 2005, a class action lawsuit was brought against the manufacturers. By 2006, with the winds blowing against them, the manufacturers voluntarily agreed to modify their bonding requirements to ensure that the unlikely event of a fire became a remote possibility. In 2009, the voluntary bonding entered the building codes, in both the International Residential Code (2411.1.1) and the International Fuel Gas Code. Quoting the former, "G2411.1.1 (310.1.1) CSST. Corrugated stainless steel tubing (CSST) gas piping systems shall be bonded to the electrical service grounding electrode system. The bonding jumper shall connect to a metallic pipe or fitting between the point of delivery and the first downstream CSST fitting. The bonding jumper shall be not smaller than 6 AWG copper wire or equivalent. Gas piping systems that contain one or more segments of CSST shall be bonded in accordance with this section."

Seems clear. One problem. It's in the IRC and not the National Electrical Code (NEC). Almost every municipality uses the NEC for their model code and this is the standard that electricians adhere to. The pipe fitters, at least in Washington, believe that they are prohibited from making this bonding connection as it may qualify as electrical work, while the electricians are unaware of the need for the bond. The end result is confusion when the home inspector properly identifies the CSST as lacking the proper bond.

According to industry estimates, there is about a billion feet of CSST installed, and much of it is in need to retrofitting.

If you want more information regarding bonding to share with your electrician, go here.

"We all fall down . . . "

Building a deck should not ever be confused with performing brain surgery or doing rocket science. It just not that hard to do it right. There is even a manual, the DCA6-12 put out by the American Wood Council, to tell you step by step how to do it correctly.

So why, on new construction, do I see something like the picture to the right? This wasn't the only problem with the deck, by the way. Flashing details were wrong and the railing was loose, to mention two other problems.

Still, the beam connection was . . . unique. I left the resolution up a bit. First, notice that the joists are attached to a 'beam'. The scare quotes are warranted. They are actually attached to a 2x6 that is cut on either end. In other words, the wood holding up the deck is unsupported from below. It's held in place by screws to the outer 2x6. The outer 2x6 is supported by a piece of untreated wood screwed into the column. It is a prescription for failure.

The DCA6 (Design for Code Acceptance 6 -2012) is a prescriptive standard for success. It has two specific means for making this connection so it is safe and endures through the years.

The first is to notch the 6x6 column to allow the beam to bear directly to the column and held in place with 2 1/2-inch through bolts with washers.

The second method is to have the beam bear to the top of the column and use a post cap to secure the assembly together.

Both of those methods are code-approved and have been for years. Which you use depends on the size of your beam and the elevation from the ground.

Sadly, not enough contractors keep up with the changes and continue to build the way Uncle Bob did back in the day. It's not that hard. The design standard is a free download from the AWC site. Every inspector should have the DCA6 on their field computer for fast reference.

For those of you interested in the nitty-gritty details of deck construction, studying the DCA6 is a great place to start. For those who just want to make sure their inspector has done the studying, make sure they have read and understand the standard. It's your family, or your client's family, that is having a party on the deck.

Is Your Crawlspace Holding Its Breath? Crawlspace Ventilation

In the old days, when curmudgeonly grandfathers ran home maintenance, they'd go close off all the crawlspace at the first indications of frost. The reasoning was simple - once winter set in, leaving the vents open would chill the occupants and freeze the pipes. Best to close them early.

Those old houses, built up through the 1960s often had no insulation in the floor of the home. Heat rises (it doesn't, really, but hot air does) so they did not see the need to waste the money on insulation in the joist cavities.

Fast forward from 1940 to the oil shocks of the mid-1970s and suddenly we were greeted with a renewed interest in energy conservation. We increased attic insulation levels, moved from four-inch exterior wall framing to six-inch and, surprise, found that insulating the crawlspace made a lot of sense.

Grandpa still closed the vents, though. Old habits die hard.

What no one explained to them was that the vents for the space are designed to relieve moisture from the sub-grade spaces. Once we moved the thermal barrier into the flooring system, there was no reason to close them as getting water vapor out far exceeded any energy savings.

The current code is to have at least one square foot of ventilation opening per 150 square feet of floor area with an opening located within three feet of corners. Obviously, home inspectors don't measure this. Still, we can eyeball it and, more importantly, can identify problems that arise from improper venting.

Reporting on the crawlspace ventilation is a mandatory part of a Washington State home inspection. WAC 308-408C-150 states, "Insulation and ventilation. The inspection of the insulation and ventilation includes the type and condition of the insulation and ventilation in viewable unfinished attics and subgrade areas as well as the installed mechanical ventilation systems. (1) The inspector will: Inspect the insulation, ventilation and installed mechanical systems in viewable and accessible attics and unfinished subfloor areas"

The purpose of ventilation, moisture removal, makes a big difference in the overall health of the crawlspace and the structural components located in there. High moisture levels lead to potential pest intrusion and mold growth. Subterranean termites and anobiid beetles both require sufficient moisture to thrive. Obviously, as homeowners, we want the exact opposite. Both of those articles I linked to point out the importance of adequate crawlspace venting.

So, leave the vents open, insulated the floor, and make sure the vapor barrier is in great shape.

Safety Glass

Last year, the Home Inspector Licensing Advisory Board for the state of Washington attempted to upgrade the Standards of Practice. Early this year, the inspector community had their chance to respond, and they showed up at the rules hearing in Olympia - and they brought their pitchforks.

I was actually happy to see them as I think that the inspectors tend towards apathy most of the time. All of the proposed changes had been discussed at multiple meetings previously, on both sides of the state, but until the rules came down, no one seem to care. As a Board member, I had no role at the rules meeting, but I - along with most of the other Board members - to hear from our fellow inspectors.

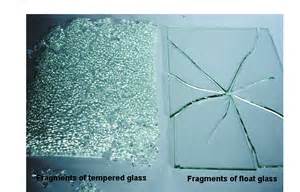

One of the proposed rules, and the second most contested, was about safety glazing. Watch any cop show and at some point somebody is going to collide with a windshield, leaving that distinctive spider-web of crazing on the glass.

That's safety glazing (safety glass) in action. Safety glazing is used to make the failure of the glass when it fractures less hazardous by minimizing the dagger-like shards that typical untreated glass crystal forms.

Two arguments were offered in opposition. The first was that identifying safety glass is outside the scope of every single Standard of Practice. This statement is truthful but incomplete. ASHI doesn't include it in their Standard of Practice, but then has an article on "Six Things Your Home Inspector Will Look For." There is a lot of good information in the article, but this quote was most interesting in light of the discussion we are having in Washington State.

"Safety should always be primary to the home inspector -- always," says Troy Bloxom, president of the National Association of Home Inspectors and owner of Home Inspections Plus near Anchorage, Alaska. . . . . Safety glass: Are the glass features installed near stairs or water (like tubs and showers), made of safety (or "tempered") glass?

InterNACHI doesn't have it in their standard, either - but has an article to train inspectors to identify it.

The second point against it was how many people really get hurt because of a glazing failure. Do we really have a problem that needs fixing?

Safety glass first entered the codes in the mid-1960s as a result of numerous lawsuits against glass manufacturers. By 1966, a working standard was developed and the Glazing Industry Code Committee pushed hard for its adoption nation-wide. A great discussion on this and a detailed look at safety glazing can be found in Doug Hansen's article Safety Glazing, published by . . . ASHI.

The short version is that the glazing industry successfully lobbied for safety glass. It's been in the codes for the better part of four decades and predates such safety devices as GFCI receptacles.

Yet, while the Ground Fault Circuit Interrupter is an item in all the inspector Standards of Practice, the more venerable safety glazing gets ignored. Using the data from Hospital-Data.com, we can get some numbers. 2010 is the last year that I could get data, so we'll use that for our baseline.

In 2010, the data indicates there were 2637 injuries that required emergency treatment - for electrical shocks. This almost certainly underreports the incidence rate of shock and probably the rate of physical injury (burns, mostly.) So let's take that number and quadruple it, to 10,000 events.

The number for window injuries? 110,322. In one year, 2010. Now, a caveat. Where the electrical data understates the rate, this number greatly overstates the injury rate that we can attribute to glazing failures. I had to dig into the numbers, looking at each case to find those that could reasonably fit my criteria. "PT {patient} WAS PLAYING WHEN A WINDOW FELL AND SHUT ON PTS LEFT HAND. D: CLOSED NONDISPLSACED FX OF LEFT HAND" clearly is a different problem, and not a result of the glass shattering.

On the other hand, so to speak, we have "13 YO M, C/O CUT TO RT 2ND AND 3RD FINGER AFTER PUNCHING A WINDOW B/C M OTHER WOULD NOT ALLOW HIM TO USE COMPUTER, DX FINGER LACERATION." We can't know whether or not the window this teen punched was safety glass protected. We can say that if it was, the injury was probably far less than he would have otherwise suffered.

In all, about a third of the incidents mentioning windows involved breakage. So, in a single year, the injuries resulting from glass was three times higher than our inflated rate of shock from receptacles.

So why are GFCI's a mandatory part of inspector standards and not safety glass? In a word, liability. The GFCI is easy to spot. Safety glass? Not so much, especially older pieces. Nowadays, we mark the glass which makes it a bit easier to identify. That wasn't the case in the 1970s and 1980s. Guessing about those glass panels is a guessing game. While there are tests we can perform with polarized lens and light, they are not practical for working in the field as an inspector.

After doing the research and seeing the numbers, I modified my inspection software to include mention of safety glass. On those occasions where I can efficiently identify the glazing, I comment on that. And, if I can't, I now explain the significance to the client with a recommendation to upgrade the glazing in the danger zones - next to walking surfaces, sliding doors, bathrooms, etc.

I think the Standards should be changed to reflect the actual risks that homeowners (and their children) face. It would not be hard to include a statement that says, "Glazing manufactured prior to the 1970's was usually not tempered and many time glass manufactured prior to 2010 was unmarked, preventing positive identification of safety glazing. Untempered glass can shatter into shards under impact. Recommend consulting a glazing contractor to upgrade windows and doors that may be at risk in order to improve homeowner safety."

Now I just have to convince the other inspectors.

Sub-Commttee Meetings 5-26-2016

The Washington State Home Inspector Licensing Advisory Board is having Sub-committee meetings next Thursday. The meetings will be held in Olympia.

For the schedule, head to the DOL site and scroll down.

Earth to Wood Contact with Treated Lumber

Lately I’ve been answering calls on why I call out deck posts that are in contact with soil on my home inspections. As one homeowner pointed out, treated lumber is allowed to be used per the International Residential Code. To his surprise, I agreed. Specifically, R317.1.2 requires that wood with ground contact be treated but allows for ground contact and burial.

I still call it as an issue. The reason is pretty simple. I am required to by the State of Washington Standards of Practice. In WAC 308-408C-070 Structure, Section 1(b) states that the Inspector shall “Report all wood rot and pest-conducive conditions discovered.” The Standard is quite explicit. Regardless of functionality, I have to report it.

The argument against reporting is that the lumber is treated so not a conducive condition. Unfortunately, this doesn’t hold. Washington State has a legal definition for what constitutes a conducive condition. That definition can be found in WAC 16-228-2025 Conducive conditions. There are a whole slew of conditions listed. The one we need is at (2) Conducive conditions include, but are not limited to, the following: (a) Earth in direct contact with wood or inadequate clearance between earth and any wood or material subject to damage from moisture.”

Again, very clear. Note also, there is no exemption for treated lumber. I’ve had people suggest that I could probe below the surface and, if there is no wood destroying fungus (wood rot) present, sign off on it. Two problems – first, depending on burial depth, I might not be able to probe the entire piece. Second, the IRC, in the same section, R317, that allows ground contact, mandates in R317.1.1 that all “field-cut ends, notches, and drilled holes of preservative treated wood shall be treated in the field in accordance with AWPA M4.”

I have never seen any contractor field treat wood, period. If the deck post has been cut, we have an issue.

Earth to wood contact is always a reportable condition for a home inspection conducted to Washington SOP’s – as all within the state are required to be, despite the conflict with the IRC.

Building Permit Research

Curious if the home you are considering purchasing has a Certificate of Occupancy?

One of my clients was, on a relatively new (six year-old) custom home, and took the time to go down to the local Building Department to do the research. To the surprise of both of us, a CO had never been issued on the home. Since I had already referred him to a structural engineer due some very odd cracking and bowing in the walls, this was the final straw in the deal.

That was a couple of weeks ago. This past week, while resolving a disagreement on electrical bonding with a contractor, I discovered that another home that I had recently inspected never had a permit purchased or an inspection performed on a brand new roof.

If home inspections were done to the same standard as a commercial inspection, visiting the Building Department for document research would be automatic. Not so for home inspections.

Maybe that should change.

I'm am now including an add-on service for residential inspections. For $125.00, I will gather the available relevant documents including permit applications, inspection reports, and Certificates of Occupancy and deliver them to you as a .pdf file.

I am recommending this for homes 25 years old and older, homes reported to have been recently remodeled, and custom built homes. The reasoning is that it takes some time in the house's lifecycle to get to the remodel and retrofit phase. Roofs and mechanical equipment usually do not need change-out earlier. Remodels trigger their own permit requirements. Custom homes fall across a broad spectrum of professional competencies. In the case above, the builder went out of business, leaving the current owner in a major lurch.

I do not recommend it for spec-built homes. Companies such as Copper Basin and Hayden Homes are consistent about acquiring the necessary permits. They are too big to fly under the radar for the Building Departments.

A minimum of three business notice required.

Hot Attics and Home Inspections

We’re reaching the time of year where entering the attics some homes takes on all the charm of a dry sauna with itchy fiberglass strewn throughout. Already this year, I’ve had an attic over 130 degrees and a bunch that were more than 40 degrees above the outside temperature. Since high attic temperatures lead to degradation of the roof shingles, this is a problem but not the sole one and not the actual cause. It’s symptomatic of poor attic ventilation.

Poor attic ventilation presents itself differently depending on season, weather, and homeowner behavior. The high temperatures that I see now, and will until the end of summer, are one indicator. Another, in winter, is the formation of ice crystals on the sheathing, typically on the north face. Excessive humidity, regardless of season, is the third factor I look for since the attic space should maintain the same relative humidity that is present outdoors.

High temperatures can cause cracking and blistering in the shingles and greatly increase the cooling costs for the home in summer. The purpose of the granulation on the shingle is to protect the asphalt which protects the fiberglass backing materials. The cracks and blisters expose the asphalt to sunlight. The asphalt is volatile and breaks down under the impact of UV light. Obviously anything that impacts the integrity of one part of the shingle affects all of them.

Ice crystals and high humidity (same issue, different seasons) are the principle forces that drive mold growth in attics in this region. The excessive moisture also leads to deterioration of the sheathing materials in the attic. Recognizing the humidity issues early can forestall the concerns. Something as simple as rust on the roofing nails can be a good indicator of possible problems. More often than not, the insulation or ductwork below the nails will have drip spots to further confirm the condition.

All of these devolve back to ineffective ventilation. Or, to use CertainTeed’s expression, inadequate ventilation. Per their warranty information, “Any shingles applied to inadequately ventilated or non-ventilated decks . . . are subject to a reduced limited warranty period of ten (10) years and do not qualify for the SureStart Protection.” In other words, that 30- or 40-year shingle is now only warrantied for a small fraction of the original and on a limited basis at that. Most, if not all, manufacturers have similar provisions.

Interestingly enough, inadequate ventilation is not defined in their literature. I had to call them to try and nail down the answer. Carl from the Technical Support department was great and dispatched a copy of their ventilation requirements from the Applicator Manual. For a balanced system where the air intake at the soffits represents 50 percent or more of the ventilation, they recommend one square foot of Net Free Ventilation Area. NFVA is basically how big a hole we need to get the proper amount of air flow.

The calculations are pretty easy. Execution of the project, though, tends to fall short. The two most common causes for poor ventilation, assuming the proper calculations have been made, are covering the soffit vents with insulation (or sealing with paint) and not properly cutting the ridge vent.

Blocking soffit vents most often happens when people add insulation to the attic space. In the attempt to improve the home’s efficiency, they inadvertently makes matters far worse, doubly so if the homeowner creates a damp atmosphere in the home by showering without using the ventilation fans or does a lot of cooking that releases moisture. Without the input pressure of air, the attic space retains the moisture.

Painters don’t help when they paint over the soffit vents. Remember that the criterion is Net FREE Ventilation Area. Fill all the little gaps with a good quality exterior paint and we no longer meet the definition.

I’ve had attics with blocked soffits measure at better than 70 percent relative humidity while the exterior of the home measured under 30 percent. You can smell the problem in these attics as soon as you pop the access cover. This is usually more discoverable in the winter and spring seasons here—our summers and falls are typically too dry to make the humidity a reliable guide. Mold, if present on the sheathing, makes the call easy. Ditto for ice crystals on the sheathing. While pretty, they need to go away.

Ridge cut with less than an inch of opening, reducing the vent by a third.

Ridge vents have their own issues. The most common installation error is failing to cut the vent wide enough. CertainTeed (not picking on them – they’ve been most helpful!) requires an opening of 1 ½ inches for trusses construction and 3 inches for rafters. Most failures I see here are undercutting the required width. This restricts how fast hot or wet air can exit the attic, even assuming the lower vents are doing their job.

Unfortunately for the home inspector, there is no recognized standard for how hot is too hot, so we end up with roofing contractors arguing that they built to code (defined as the worst house you’re legally allowed to build) while we argue about actual performance. I use a level of 20 degrees of differential in the outdoor and attic temperatures. At that point, improving the attic ventilation becomes a recommended upgrade unless I see worrying signs of moisture build-up. At 40 degrees, it becomes a recommended repair as there is almost always a significant defect in the system at that point.

Some helpful resources:

http://www.factsfacts.com/MyHomeRepair/ventilation.htm

http://buildingscience.com/documents/digests/bsd-102-understanding-attic-ventilation

https://www.energystar.gov/index.cfm?c=diy.diy_attic_ventilation

Why Remove the Service Covers?

Part of the Washington State SOP is removal of the access covers for furnaces. It seems like a bit of common sense, but not every inspector will do it, especially if the furnace is relatively new or electric.

Yesterday's inspection gave me a great example of why the cover should be removed. The induced-draft furnace, a Carrier wasn't that old. It was a bit of a problem to get to it since the builder put in the crawlspace.

Before I clambered into the under-floor area, I set the thermostat up by ten degrees so I could put a heat demand on the system. When I reached the scuttle, I could hear the inducer spinning up and the furnace ignite. All good.

I let it run while I did the crawlspace inspection (also required under Washington's SOP.) After taking pictures of the issues there, I turned my attention to the furnace.

It was side-mounted with the burners to my left and the blower compartment to my right. To get the cover off for the burners, both covers needed to be removed. This shut down the whole furnace, as it should, when the blower door safety switch released.

I fiddled with the blower door and remounted it with it to restart the furnace which obligingly did so. Saw the glow of the hot surface igniter and heard the woosh of the gas burning. And, from the corner of my eye, an oddity. The flame on start-up didn't look right. A few seconds later, the furnace shut down on its own.

Most modern furnaces has a sight glass to the electronic control boards. On these boards, there is an LED (light emitting diode) or two that will signal an error code. In this case, it was three short lights followed by three long. The legend indicated a flame roll out or limit switch failure.

I used the serviceman's switch (a switch located within sight of the piece of equipment that turns power off to it) and reset everything. The furnace started, ignition, and ran without incident.

Have I mentioned I hate intermittent problems?

So I reset everything, again.

And the furnace failed, again. This time I got the (not very good) picture of the flame roll out. If you look closely to the left side of the picture, a tongue of flame dodges the normal flame path and appears to be hitting a wire.

If I had taken the easy way, to start the system and count it as working by just the first start-up, I would have missed a critical detail of the operating status of the furnace. By pulling covers and testing both safety switches, I gathered better and more accurate information. Better still, I found a condition that might lead to a house fire. Protecting the people in that home is the most important part of my job.

The cost of repair probably isn't much, in this case. I say probably because, while the issue may be as simple as adjusting the gas and air mixtures, a cracked heat exchanger can present this as well. In that case, replacement of the whole furnace may be necessary. In between, the venting of the furnace may be a cause.

As a home inspector, determining the cause is beyond my purview. Finding it, though - that's solidly in the inspector wheelhouse.

Last Day of Work This Year - December 23rd

Hi:

By now, I think that nearly everyone that I work with on a regular basis has heard that I will be taking an extended period off from performing inspections in order to travel to Africa. Not everyone has the timeline, so I thought I would share that so each person can plan for the future.

I leave for Kenya on December 27th. With the holiday, that means my last day of work for the year will be the 23rd, as I am also taking my birthday (Dec. 24th) off to spend with my family.

I return, assuming no unfortunate incidents with hippos or lions, on January 29th and will be ready to work on February 1st.

The trip is a combination of research for a new novel and a chance for me to realize a lifelong dream to explore, at least in small part, the incredible continent that is Africa. It also follows a realization that the time for such a trip is while you are both young enough and healthy enough to maximize the adventure.

For those who wish to follow along, I will be posting to my personal blog, www.paulduffau.com, but Internet service is likely to be spotty in the Rift Valley.

I thank you for your understanding and hope that this does not unduly inconvenience you. I did try to schedule the trip to take advantage of the slower winter season.

My best wishes to all,

Paul Duffau

Aftermath of a Big Wind Storm

I have a lot of clients that are a little freaked out by the storm last night so I'm clearing some time on my schedule to do drive-bys on their homes that are under contract. If you have a client that is still under contract and worried, let me know and I'll set up a time to get to property. This is a freebie service, btw.

On Thursday 11/19, I'm in Pullman.

Saturday 11/21, I can be in Moscow.

Some Problems Really are Intermittent

We have had some desperately-needed rain here in the Palouse over the last week or so. It good for the crops-the winter wheat is sprouting-and for home inspections. Most people think of roofs when they consider the helpfulness of rain during the inspection, but there are other features that can make themselves apparent.

In this case, it appeared that the underground drainage system for the storm water off the roof was blocked, so I had water overflowing the boot at the downspout. Unsurprisingly, this manifested as a water problem in the crawlspace in the same corner.

Half the battle in fixing water problems is understanding where the water is coming from. In this case, it was easy to present the client with the results of the inspection and a potential course of action to correct it.

Pipe Organs, from the inside

I can add to my list of firsts. Today, the inspection was at a church in Moscow and they had a pipe organ, so I had a chance to crawl around on the interior. Very neat to see the different structures that they use to create the sounds. Also, the wiring is impressive as heck.

Nobody ever said this job was boring!

Each one of those represents a different circuit to activate the pipes. Wickedly complex.

The mid-sized pipes. Look like they're out of a Disney movie.

The tops of the largest pipes were twelve feet over my head.

Houses Don't Levitate

I know we're closing in on Halloween, but last time I checked, house framing doesn't float in the air above the foundation wall like Casper the Ghost. There's a reason inspectors need to physically enter the crawlspace.. Here, the floor joists are a half-inch from the sill plate and there's also a gap below the sill plate (and no anchor bolts to be found!) Add to it cracks in the wall an inch or more wide with substantial deflection, and yep, I punted. This is one for a structural engineer like Evan Laubach of Pullman. He's terrific at finding solutions to major issues, usually in a cost-effective manner.

Order and Pay for Everything Electronically!

I've been making changes behind the scenes for the website. Among those changes are the ability to sign the inspection agreement online (just head to the Agreement tab under ABOUT) and, the latest change, the ability to prepay the inspection at the same time that you schedule.

As with everything I do, I aim for the most comprehensive level of service and convenience for you, while providing you with a great inspection.

Thanks - and if you have other suggestions on how I can make this process easier for you, let me know!

Autumn Joys

We're in the midst of a change of seasons to my favorite of the year - autumn. The heat of summer gets broken and replaced with simply warm afternoons and brisk nights. The trees begin their turn to ornaments, just ahead of becoming yardwork.

With the press of summer past us (not that work has slowed appreciably), let's celebrate the beginning of a new autumn.

By all these lovely tokens September days are here, With summer's best of weather And autumn's best of cheer. ~ Helen Hunt Jackson

I trust in nature for the stable laws of beauty and utility. Spring shall plant and autumn garner to the end of time. ~ Robert Browning

And, lastly, because it suits my mood:

Autumn's the mellow time. ~William Allingham

Enjoy the week!

Traversing Attics

I have a few tricks for traversing the attic without destroying the insulation. One is to take advantage of physics by anchoring in more that one plane. In this attic, had my thigh leaning into the web on the left while my foot took the load on the bottom side. Traversed the whole attic with nary a footprint in the fiberglass.

Relax and have fun!

Just play. Have fun. Enjoy the game. ~Michael Jordan

If you obey all the rules you miss all the fun. ~Katharine Hepburn

Never, ever underestimate the importance of having fun. ~Randy Pausch

Have a great week! Don't work too hard and have a little fun!

Washington State License #215

Former SBCC Member, Former Chairman State Home Inspector Advisory Licensing Board.